L60+ Thermocouple Welder

The popular and versatile thermocouple welder instrument comes complete with all accessories for use. Add additional accessories as required.

Read our product spotlight article on the L60 Thermocouple welder

The L60+ Thermocouple Welder & Fine Wire Welder, manufactured by Labfacility, is a compact, simple-to-use instrument designed for thermocouple and fine wire welding.

It is primarily designed for use by sensor manufacturers to produce commercial grade thermocouple junctions; it is ideal for producing large numbers of exposed junction thermocouples for test and development laboratories. The L60 Thermocouple Welder is ideally suited to transducer and RTD extension lead attachment.

Use of the Thermocouple Welder does not require special skills and most operatives will be capable of producing quality work with little practice. The instrument is supplied with a full range of user accessories including a footswitch.

Suitable for use with wires of up to 1.1mm diameter an argon gas shield facility is included but a satisfactory thermocouple junction is produced without the need for argon. The output energy of the L60 Thermocouple Welder can be varied up to 60 Joules.

- Simple to use Thermocouple Welder

- Designed for the production of commercial grade thermocouple junctions

- Also suitable for other fine wire work

- Front panel or footswitch operation

- Argon gas shield facility

Supplied complete with the following accessories:

| Wire Holding Pliers & Lead | Safety Glasses | Magnifying Eyeglass |

| Argon Hose | 2 x Carbon Electrodes | Spare 2A Fuse & Mains Lead |

| Footswitch for greater ease of use |

Welder Pen & Plate |

Impact Clip |

Specifications

| General Description | The Thermocouple Welder, manufactured by Labfacility, is a compact, simple-to-use instrument designed for thermocouple and fine wire welding. |

| Dimensions | 220mm (W) x 120mm (H) x 250mm (D) |

| Power Consumption | Max 170VA dropping to 20VA during charging |

| Power Supply | 110-120 Vac or 220-250 Vac, 50-60Hz |

| Standards Met | BS EN / CE |

| Energy Output | 0-60 Joules |

| Duty Cycle | Minimum 5-10 welds/min |

| Welding Capacity | Wires up to 1.1mm diameter |

| Argon Pressure Regulator Level | <5 bar |

| Maintenance | Apart from keeping the electrode in good order, no other maintenance is required. |

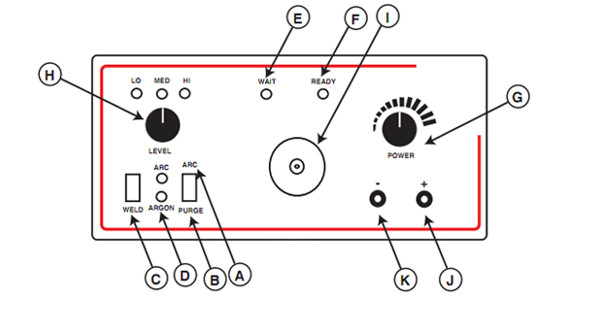

THERMOCOUPLE WELDER CONTROLS

| A – ARC |

Argon gas and weld current controlled by the “Weld” switch. LED indication. |

| B – PURGE | Allows the gas line and electrode shield to be purged of air prior to a new welding period. |

| C - WELD SWITCH | Initiates a welding operation (in “arc” mode also opens the Argon valve). |

| D - ARGON LED | Indicates when the Argon control valve is open and gas is flowing. |

| E - WAIT LED | Glows when weld charge is building. |

| F - READY LED | “Ready to Weld” indication. |

| G - POWER |

Rotary control of the capacitor charge voltage. |

| H - LEVEL SELECTOR |

Selects the total capacitance available giving the following values with LED indication - "LO" = 0 to 6 Joules "MED" = 0 to 28 Joules "HI" = 0 to 64 Joules |

| I - ELECTRODE HOLDER | Rotary control of the capacitor charge voltage. |

| J - RED SOCKET |

Output socket for using the pliers supplied. |

| K - BLACK SOCKET |

Output socket, this provides an additional earth. |

Thermocouple Welder Rear Panel

| A – On / Off Switch |

Power to instrument on / off |

| B – Weld Jack Socket | Weld Jack Socket Footswitch connection |

| C - Argon Inlet | For connection to Argon Supply |

| D -IEC Power Inlet module | For selection of 110-120 Vac or 220-250 Vac power supply. Factory default setting: 220-250 Vac |